Connection Link/ C- Link /Eye Bolt/ Eye Nut

PRODUCT OVERVIEW

The Connection Link, also known as the C-Link, Eye Bolt, and Eye Nut, is a versatile and essential component used in various applications across industries. It provides a reliable connection point and offers convenience and flexibility in rigging and lifting operations.

Specification

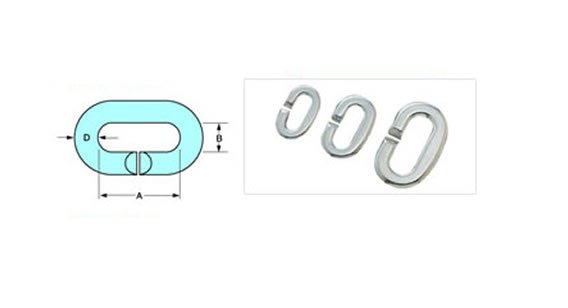

1: Connection Link

|

D(mm) |

A(mm) | B(mm) |

working load(kg) |

| 2 | 12. 2 | 3. 3 | 3 |

| 2.5 | 14 | 4. 5 | 5 |

| 3 | 19 | 5. 4 | 7 |

| 4 | 26 | 6. 2 | 15 |

| 5 | 27 | 8 | 20 |

| 6 | 30 | 11 | 30 |

| 8 | 38 | 12 | 50 |

2:"c" Link

|

D(mm) |

B(mm) | C(mm) |

working load(kg) |

| 5 | 9 | 16 | 20 |

| 6 | 12 | 20 | 30 |

| 8 | 15 | 25 | 50 |

| 9 | 19 | 30 | 100 |

| 11 | 23 | 36 | 150 |

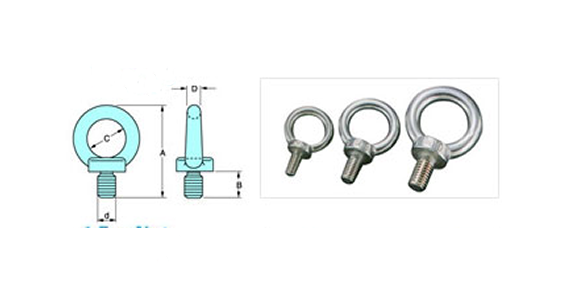

3: Eye Bolt

|

A(mm) |

A(mm) | B(mm) |

d(mm) |

| 31 | 20 | 8 | M6 |

| 39 | 24 | 9 | M8 |

| 48.5 | 32 | 12 | M10 |

| 61 | 36 | 13 | M12 |

| 72 | 44 | 17 | M16 |

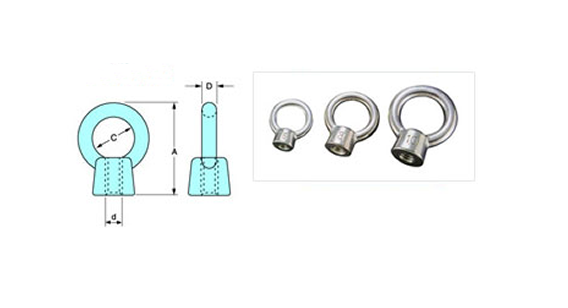

4:Eye Nut

| A(mm) | C(mm) | D(mm) | d(mm) |

| 28 | 16 | 5 | M6 |

| 33 | 20 | 6 | M8 |

| 41 | 25 | 8 | M10 |

| 51 | 30 | 10 | M12 |

| 60 | 35 | 12.5 | M16 |

Connection Link/ C- Link /Eye Bolt/ Eye Nut Applications

The Connection Link/C-Link/Eye Bolt/Eye Nut finds extensive use in diverse industries and applications, including:

Rigging and Lifting: These components are commonly used in rigging and lifting operations to create secure connections between different elements, such as chains, cables, or slings.

Construction and Industrial Applications: Connection Links, C-Links, Eye Bolts, and Eye Nuts are employed in construction and industrial settings for tasks such as lifting equipment, securing loads, and creating attachment points.

Marine and Offshore Industry: These components are utilized in marine and offshore applications for mooring, anchoring, and lifting operations. They provide reliable connections in challenging marine environments.

Material Handling: Connection Links, C-Links, Eye Bolts, and Eye Nuts are used in material handling operations to create lifting points and secure heavy loads.

Connection Link/ C- Link /Eye Bolt/ Eye Nut Features

The Connection Link/C-Link/Eye Bolt/Eye Nut offers several features that make it suitable for animal-related applications. Some key features include:

High Load Capacity

Versatility

Easy Installation

Corrosion Resistance

Durable Construction

Safety Features

Choosing the Right Connection Link/ C- Link /Eye Bolt/ Eye Nut

When selecting a Connection Link/C-Link/Eye Bolt/Eye Nut, consider the following factors:

Load Capacity: Determine the maximum load the component will be subjected to and choose one with a suitable load capacity.

Material: Select a material that is suitable for the intended application, considering factors such as corrosion resistance and environmental conditions.

Size and Configuration: Choose the appropriate size and configuration based on the lifting equipment and load requirements.

Safety and Compliance: Ensure that the component meets relevant safety standards and certifications to ensure safe usage.

LET'S GET IN TOUCH

FAQ: Connection Link/ C- Link /Eye Bolt/ Eye Nut

A Connection Link, also known as a C-Link, is a type of link used to connect two components or objects together. It is typically made of robust materials such as steel and features a loop or chain-like design that allows for secure and reliable connections.

An Eye Bolt is a fastener with a threaded shank and a looped end, shaped like an eye. It is designed to be inserted into a pre-drilled hole and secured using a nut. Eye Bolts are commonly used for lifting heavy loads or attaching cables, ropes, or chains to various structures or equipment.

An Eye Nut is similar to an Eye Bolt but is designed with a female thread inside the looped end, enabling it to be screwed directly onto a threaded rod or bolt. Eye Nuts are often used for applications where a secure point of attachment is required for lifting, rigging, or suspending objects.

When choosing a Connection Link, C-Link, Eye Bolt, or Eye Nut, consider factors such as the intended application, load capacity requirements, material strength, and the environment in which it will be used. It is essential to select a size and type that can safely handle the expected load and ensure compatibility with the equipment or structure.

Load capacities can vary depending on the specific design, material, and size of the Connection Link, C-Link, Eye Bolt, or Eye Nut. It is crucial to refer to the manufacturer’s specifications and guidelines to determine the load capacity and ensure safe usage.