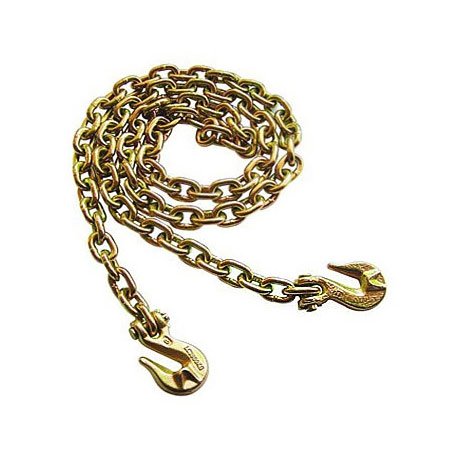

Straight chain

PRODUCT OVERVIEW

Straight chains are versatile and widely used components in various industries and applications. They provide strength, reliability, and flexibility for a range of tasks, from lifting and securing loads to rigging and hoisting operations.

Specification

|

Trade Size |

Material Diameter | Proof Test (Min) | Minimum Breaking force | Nominal Inside Length |

Nominal Inside Width |

||||||

| mm | in | 3.0 | Ibs | kN | ibs | kn | in | nn | in |

mm |

|

| 4 | 3.0 | 0.120 | 3.4 | 215 | 1.91 | 860 | 3.82 | 0.55 | 14.0 | 0.21 | 5.3 |

| 3 | 3.4 | 0.135 | 3.8 | 270 | 2.40 | 1,080 | 4.80 | 0.59 | 15.0 | 0.24 | 6.1 |

| 2 | 3.8 | 0.148 | 4.1 | 325 | 2.89 | 1,300 | 5.78 | 0.61 | 15.5 | 0.26 | 6.6 |

| 1 | 4.1 | 0.162 | 4.5 | 390 | 3.47 | 1,560 | 6.93 | 0.63 | 16.0 | 0.28 | 7.1 |

| 1/0 | 4.5 | 0.177 | 4.9 | 465 | 4.14 | 1,860 | 8.27 | 0.74 | 18.8 | 0.31 | 7.9 |

| 2/0 | 4.9 | 0.192 | 5.3 | 545 | 4.85 | 2,180 | 9.69 | 0.78 | 19.8 | 0.34 | 8.6 |

| 3/0 | 5.3 | 0.207 | 5.5 | 635 | 5.65 | 2,540 | 11.29 | 0.85 | 21.6 | 0.36 | 9.1 |

| 4/0 | 5.5 | 0.218 | 6.4 | 700 | 6.23 | 2,800 | 12.44 | 0.99 | 25.1 | 0.38 | 9.6 |

| 5/0 | 6.4 | 0.250 | 6.4 | 925 | 8.23 | 3,700 | 16.44 | 1.07 | 27.2 | 0.44 | 11.2 |

Straight Chain Applications

Straight chains have diverse applications across multiple industries, including:

Construction: Straight chains are commonly used in construction for tasks such as lifting heavy materials, securing scaffolding, and rigging equipment.

Agriculture: Straight chains find application in agriculture for tasks like towing, anchoring, and securing machinery or farm equipment.

Transportation and Logistics: Straight chains are used in transportation and logistics for cargo handling, securing loads on trucks or trailers, and material handling operations.

Marine and Offshore: Straight chains are suitable for marine and offshore applications, such as mooring, towing, and anchoring vessels and floating structures.

General Industrial Use: Straight chains are also widely used in general industrial applications for lifting, hoisting, and securing heavy objects in manufacturing, warehouses, and other industrial settings.

Straight Chain standard link Features

Straight chains possess several features and specifications that make them a popular choice in various industries. Key characteristics include:

High Tensile Strength

Material Selection

Versatility

Link Sizes

Certification and Compliance

Easy Maintenance

Choosing the Right Straight Chain

When selecting a straight chain for your specific application, consider the following factors:

Working Load Limit (WLL): Determine the maximum load the chain will be subjected to and select a chain with an appropriate Working Load Limit that exceeds your requirements.

Material Selection: Choose the material based on factors such as strength, corrosion resistance, and environmental conditions. Steel chains are commonly used for general industrial applications, while stainless steel or alloy steel chains are preferred for corrosive or high-stress environments.

Link Size: Select the appropriate link size based on the intended load capacity and the specific requirements of your application. Larger link sizes offer higher load capacities but may sacrifice flexibility.

Certification and Compliance: Ensure that the straight chain you choose meets the necessary certifications and standards for your application. This ensures its quality, safety, and compliance with industry requirements.

LET'S GET IN TOUCH

FAQ - Straight Chain

A straight chain is a type of chain that consists of interconnected links arranged in a linear configuration, without any additional attachments or modifications.

Straight chains have various applications across industries. They are commonly used for lifting heavy loads, towing vehicles or equipment, securing objects, creating barriers, and in general-purpose settings where a durable and reliable chain is required.

Straight chains can be made from different materials, including stainless steel, carbon steel, alloy steel, or other metals. The material choice depends on the specific requirements of the application, such as strength, corrosion resistance, or environmental conditions.

Straight chains are typically not adjustable in length. They come in predetermined lengths based on the manufacturer’s specifications. However, it is possible to connect multiple chains or use chain accessories like hooks or shackles to achieve the desired length.

Some straight chains are specifically designed for overhead lifting applications and are marked with appropriate certifications or standards, such as Grade 80 or Grade 100. It is important to ensure that the chain being used is suitable and approved for overhead lifting, and to follow all safety guidelines and regulations.